Discover CAM Scale-Up UK through Robotiz3d

Paolo Paoletti outlines Robotiz3d’s experience participating in the CAM Scale-Up UK Programme.

Learn more about their speciality, the testing process and the results.

Robotiz3d and the Zenzic CAM Scale-Up UK programme

Developing autonomous technology to identify and repair potholes in UK roads

In the UK alone, the toll of potholes is striking, with one cyclist injured every week and vehicle damage claims totaling around 4 billion per year.

And as electric vehicles rise in popularity, the weight our roads need to withstand to facilitate cleaner, greener travel is increasing too. It’s clear that the way we are maintaining our road is not working.

Robotiz3d is therefore addressing a need that we are all familiar with.

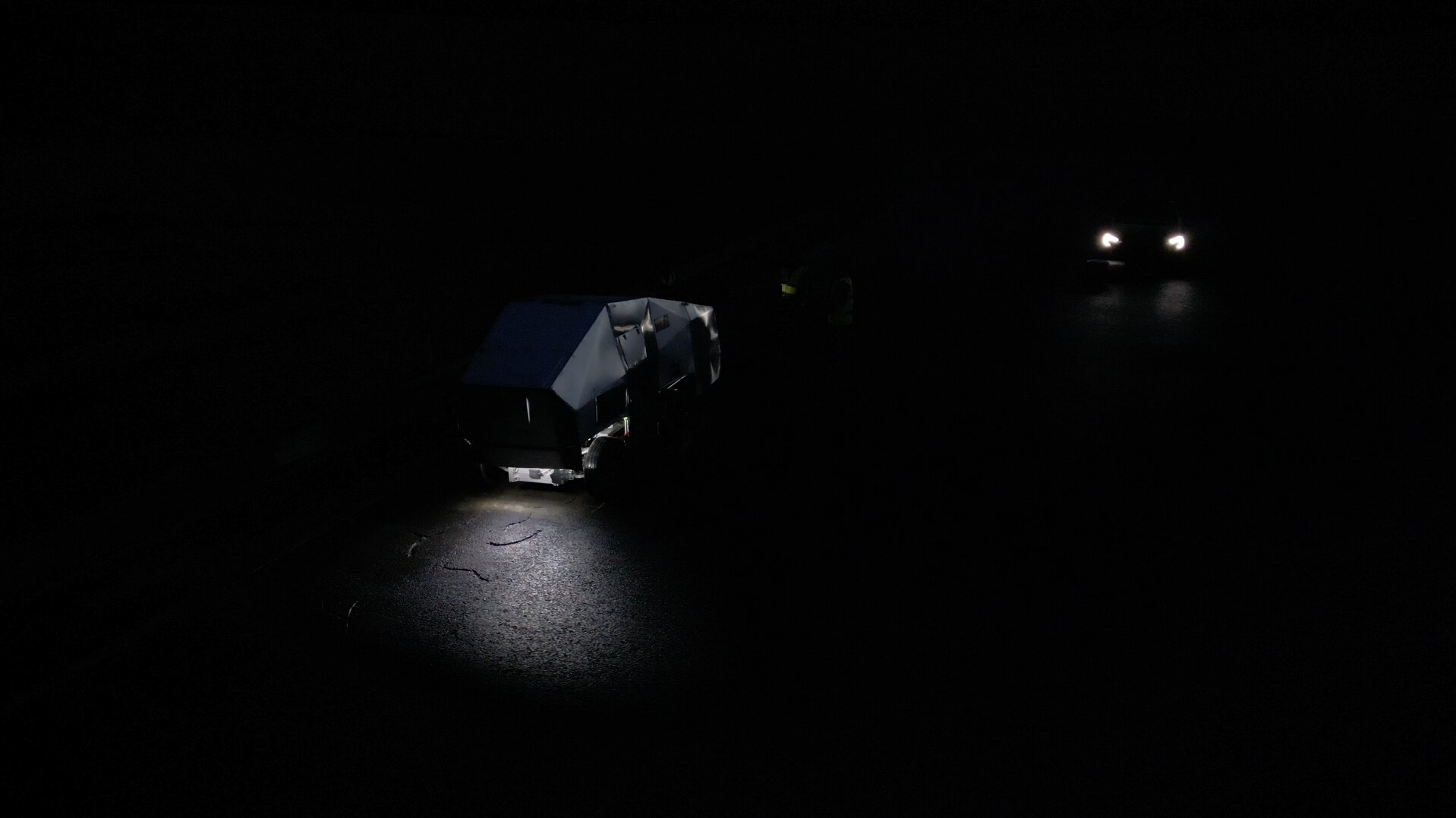

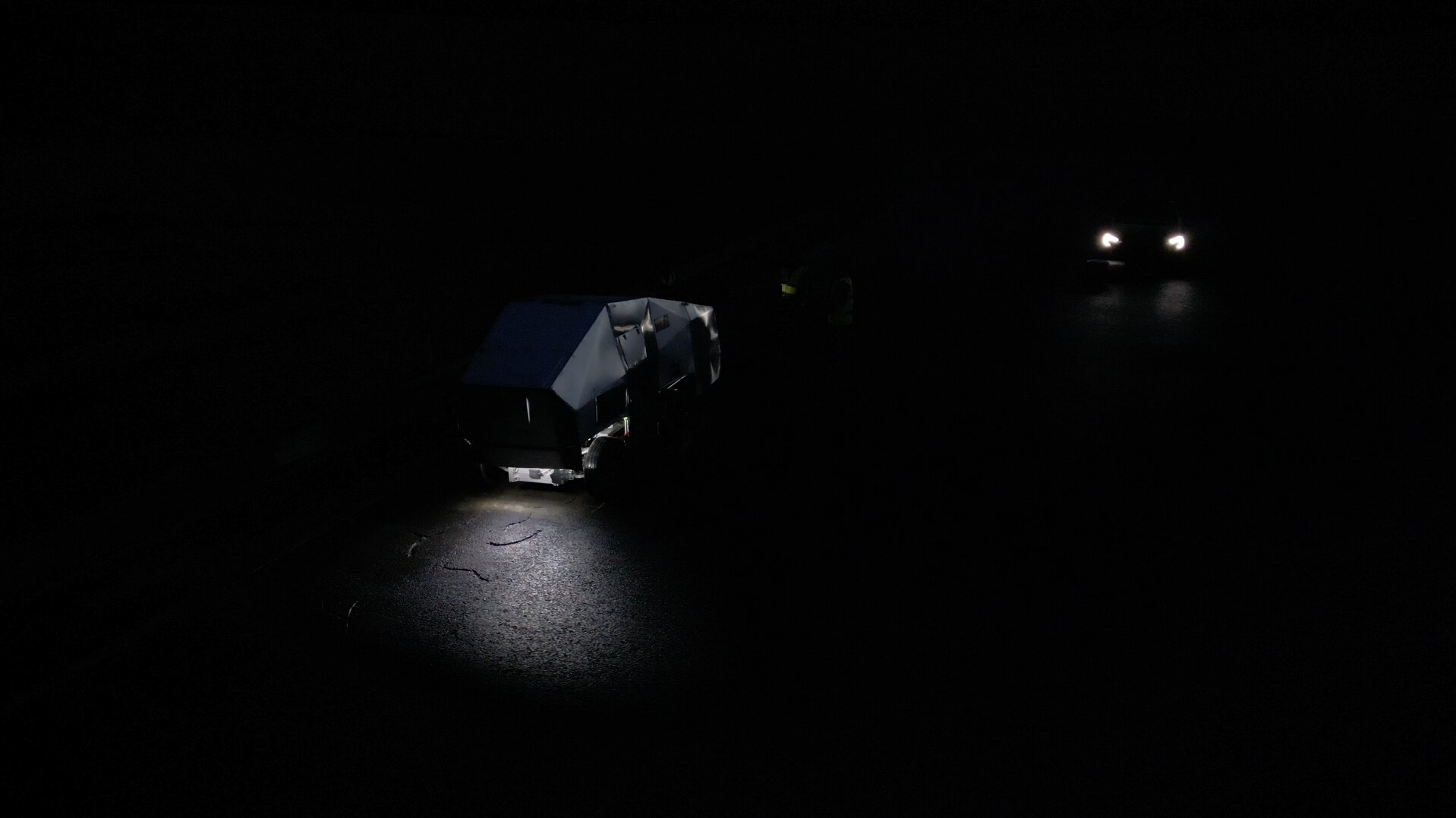

Their core innovation centers on integrating autonomous vehicles with their bespoke sensing and 3D printing technologies. This enables the creation of autonomous vehicles capable of precisely detecting, characterising, and then sealing cracks in roads without causing damage to the surrounding infrastructure – all without human intervention. Through this innovative solution, Robotiz3d is revolutionizing road maintenance, offering a promising path towards safer and more resilient transportation infrastructure.

Paolo explains

“What we have is a difficult product, which basically embeds artificial intelligence, robotics sensing, and so on. Our core innovation in terms of sensing is our bespoke sensing technology, which is a laser based opposed to a vision base, which is what most of our competitors use, and the unique benefit that we can provide therefore is an accurate measurement of the depth of the defects.

We can work basically in any weather condition, and actually we can work 24-7

because especially at night there is no sunlight, and actually, our sensor works even better.”

What makes Robotiz3d special?

Robotiz3d is a spinoff company from the University of Liverpool. Their mission is to revolutionize the road maintenance sector by introducing automation and autonomous platforms, so that roads are safer for the user, and the job of

maintenance job is more sustainable, safer and more efficient for road asset management.

Their development is split into three phases:

Firstly, ARRES Eye, a cutting-edge solution designed to meticulously sense defects and characterize road conditions with unparalleled precision.

Next in line is ARRES Prevent, where detected cracks are promptly sealed by an autonomous vehicle, preemptively averting the formation of potholes.

Lastly, ARRES Ultra promises to elevate road maintenance capabilities further by not only sealing cracks but also effectively repairing potholes, offering a comprehensive solution to address road infrastructure challenges. Through these progressive phases, Robotiz3d is poised to revolutionize the road maintenance landscape, ushering in an era of enhanced safety, sustainability, and efficiency.

Paolo tells us:

“Up to now we have fully developed ARRES eye, which is our first product. It’s on the market now, and we have a working prototype of ARRES Prevent, that we are currently trialing.”

Robotiz3d’s Testing Journey

Utilising the expertise and facilites across CAM Testbed UK to test and validate their products

For Robotized, having access to CAM Testbed UK has brought two key benefits.

The first is access to experts, particularly in terms of regulation and certification of their products, as this is an expertise that they do not possess internally.

The second is access to test beds where they can test their technology,

getting quantitative evaluation of performance of the technology in real-world scenarios that they can then showcase to potential customers.

They chose Smart Mobility Living Lab: London for testing ARRES Eye to benchmark their solution against what is considered to the the state of the art system on a live environment of public roads in and around Greenwich, providing them with a third party evaluation of the efficacy of their system.

And they chose UTAC Millbrook to test their ARRES Prevent crack detection and sealing prototype, as this brought the option of damaging the roads, to then fix them and check the performance of the prototype under different weather conditions, and different types of cracks. This facilitated the fine-tuning of AI parameters and again gain an independent validation of the prototype’s performance.

“Our customers had been asking for independent valuation, and by the end of the CAM Scale Up UK program we had this evaluation and therefore we were able to show this.

Both testbeds provided advice that might guide our future development.

We had advice on how to integrate ARRES Eye and our technology in the current workflow from SMLL.

And also we got a report at the end of the of the program from Utac in terms of what kind of certification we might need for putting ARRES Prevent on the market.”

What does success look like?

“I’m very excited about the work we are doing in this company because it’s so cutting edge that we are really exploring the unknown and we need to come up with such a solution to the problem that we’re facing.

We are of course a start up, looking to scale up, so we are going through continuous round of investment and therefore being able to showcase that our technology works and having this validated by a third party has given a lot of confidence to our investors that actually what we’re developing is useful for the market.”

Paolo concludes

“So if we get this right, I think we’ll enable councils and road asset management to basically save millions.”

{{ teamMember.name }}

{{ teamMember.title }}